The HVAC market is still on an upward curve in the UK, with forecasts pointing to steady growth over the next decade.

That’s the good news.

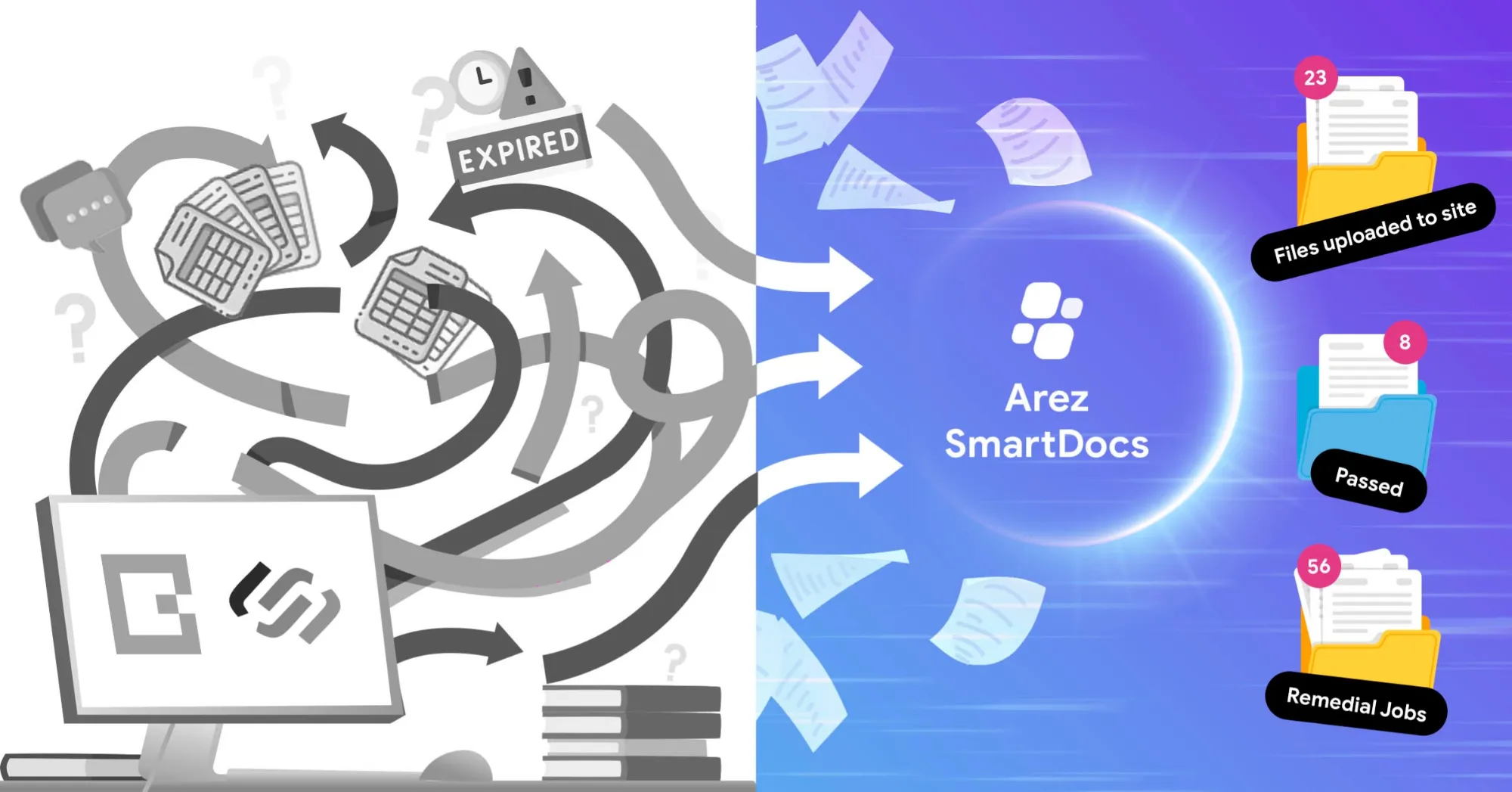

The less-good news: growth has a habit of turning into more jobs, more admin, more stress, and somehow less margin, especially once you’re managing multi-site customers, PPM schedules, subcontractors, compliance evidence, and invoices across the UK and EU.

If you’re an owner, director, or Ops lead, this is the strategic bit: you don’t scale HVAC by hiring endless coordinators. You scale by building an operation that can run a big book of work with a lean, A-players team.

Here are the three challenges that determine whether you scale profitably or simply become busier.

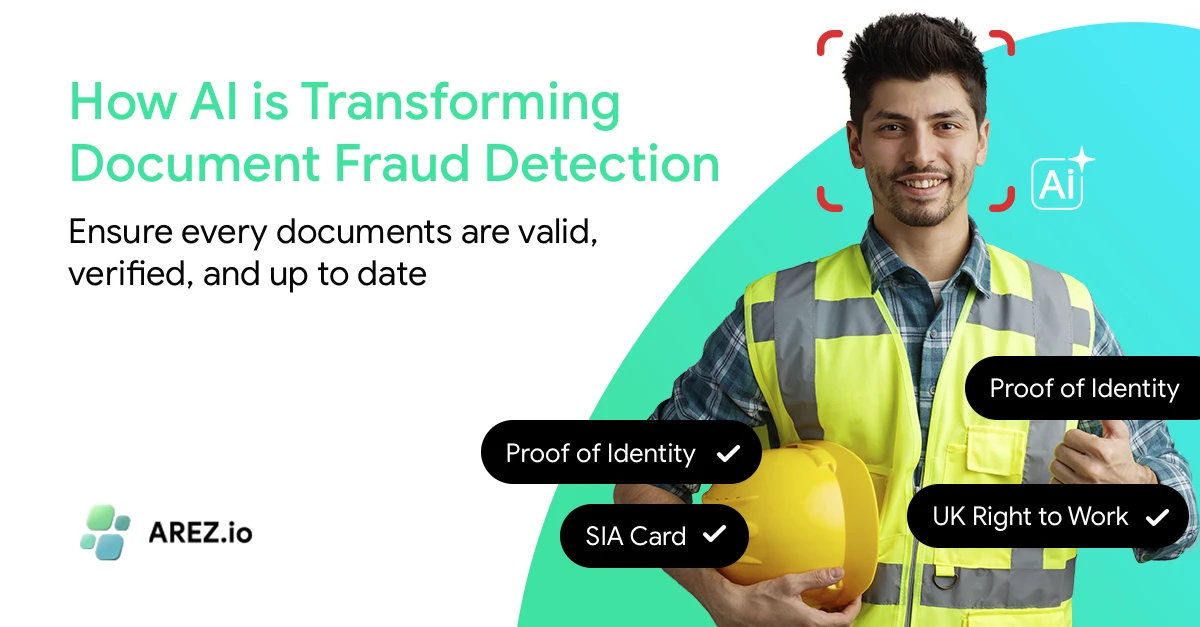

Compliance that doesn’t collapse under scale

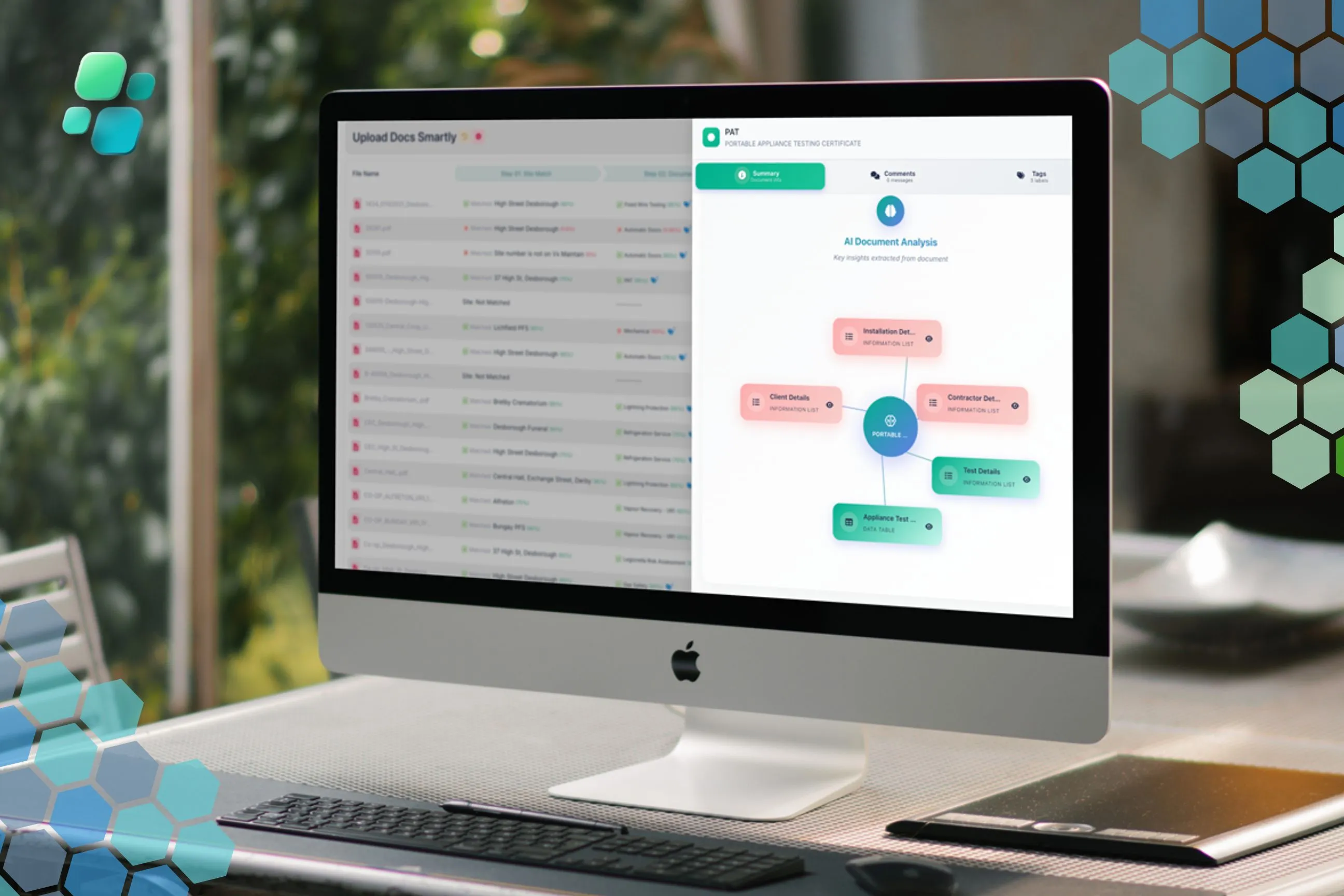

In HVAC, compliance isn’t “a folder”. It’s proof: who did what, where, when, what refrigerant was handled, what checks were completed, and what evidence exists when someone asks awkward questions six months later.

Across the UK, enforcement activity has included millions in civil penalties for breaches of fluorinated gas rules in recent periods.

Across the EU, the direction of travel is the same: tighter control, stronger documentation expectations, less tolerance for “we’ll find it later”.

The lean-team fix

Make compliance the by-product of the job, not a second job.

- Mobile checklists completed on-site (time-stamped, user-stamped)

- Refrigerant logging captured at the point of work

- Certificates/photos automatically attached to the right job + site, + asset

- Audit exports in minutes, not in a mild panic

SEO magnet line (true and useful): If you’re searching for HVAC compliance software or F-Gas compliance software, what you really need is structured evidence, automatically produced while work happens.

Cashflow + margin leakage (the silent killer)

You can be fully booked and still feel broke if you’ve got:

- repeat visits,

- unnecessary travel time,

- Jobs stuck “completed” but not invoiced,

- and a back office spending half its life chasing updates.

Late payment alone is estimated to cost the UK economy almost £11bn per year.

Directors don’t need another lecture on cash flow, they need a system that stops cash flow being held hostage by admin.

The lean-team fix

Tighten the “job → sign-off → invoice” pipeline until it squeaks.

- Smart scheduling that reduces dead time and drive time

- Digital job sheets + instant customer sign-off

- Invoices generated from job data (no re-keying, no delays)

- Job costing visibility (labour + travel + parts) so margin doesn’t quietly evaporate

Funny-but-true: “We need more admin” is usually code for “our process is leaking”.

Asset chaos (the reason first-time fix, PPM and trust fall apart)

If engineers arrive without accurate asset history, model/serial, location notes, previous faults, and what was tried last time… you’re basically funding a live experiment on your own margins.

First-time fix is a huge operational lever. “Best-in-class” field service organisations are often cited as resolving issues on the first visit around 88% of the time.

The lean-team fix

Build an asset register that engineers will actually use (not a spreadsheet museum).

- Live asset register by site

- Standard fields (location, make/model, serial, capacity, refrigerant type, where relevant)

- Job history attached to the asset (photos, notes, certificates)

- QR codes so the engineer scans and instantly sees what matters

This is where HVAC asset management stops being “nice to have” and becomes: fewer repeat visits, faster diagnosis, smoother compliance.

The strategic point: you can run a huge HVAC business with a lean A-players team (with Arez)

This is the director-level advantage.

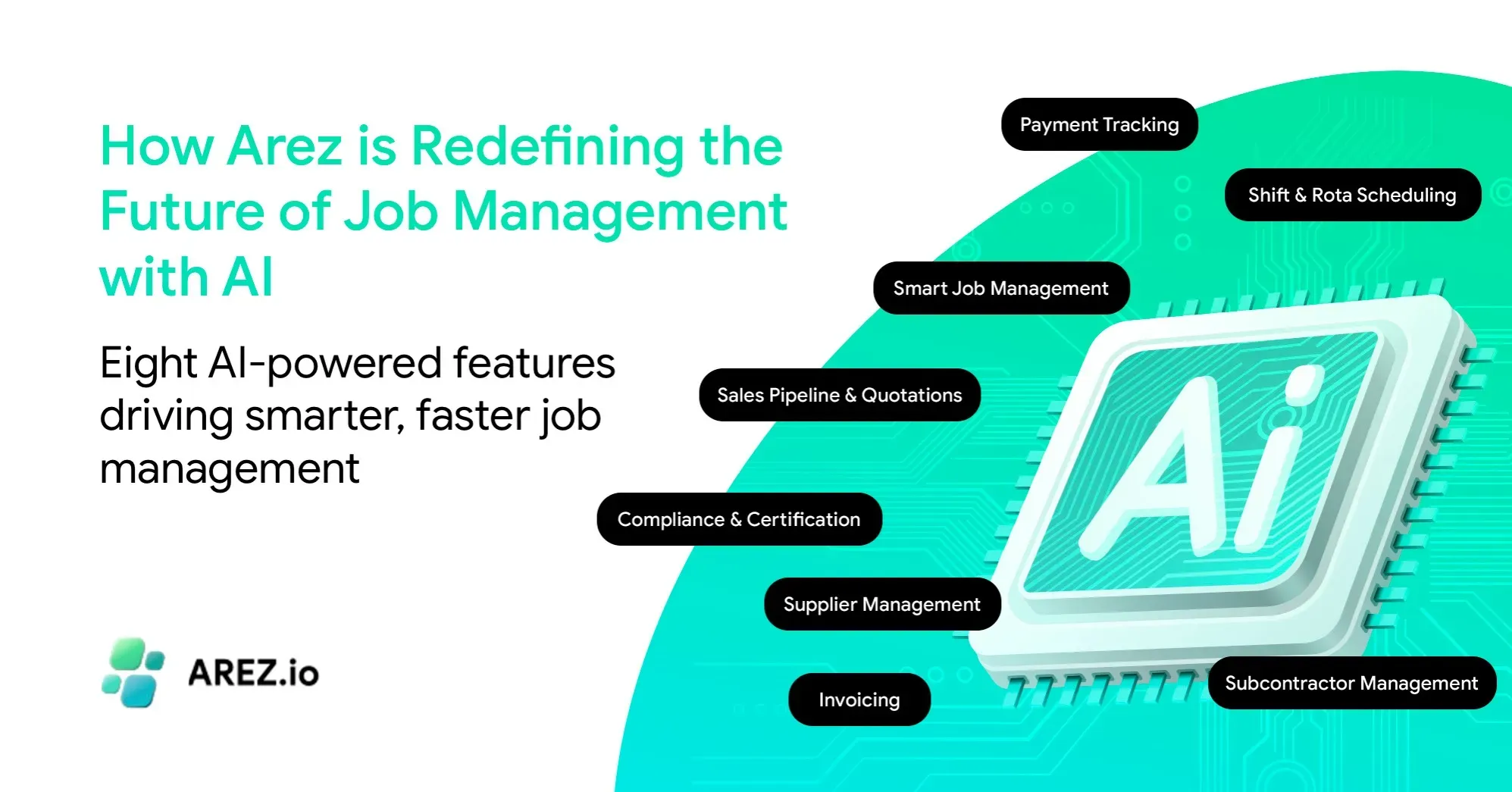

Arez is designed so that the platform carries the operational load:

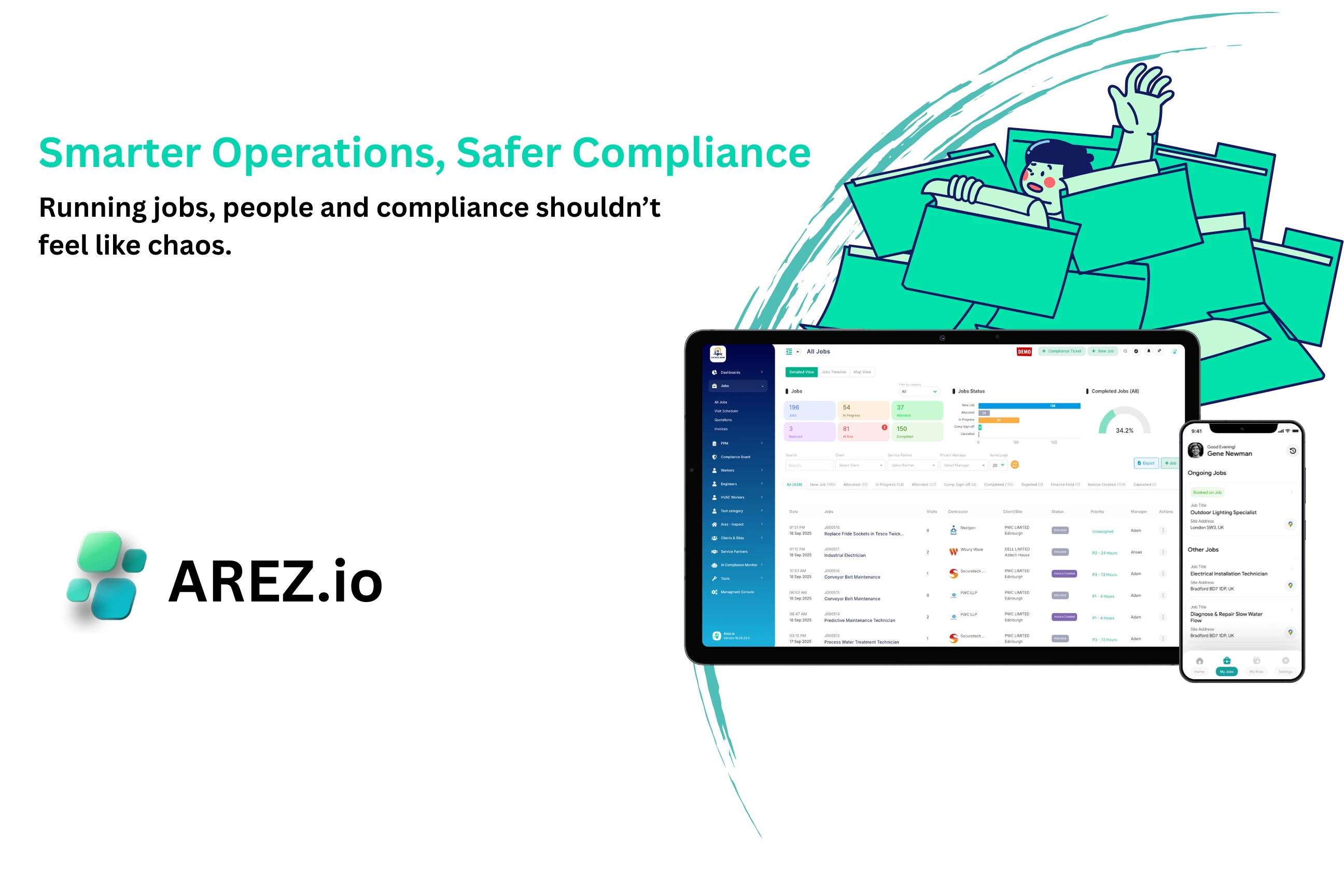

- Jobs, scheduling, assets, compliance evidence, and invoicing are connected end-to-end

- Information is captured once, at source, as work happens

- Audit trails exist by default

- reporting isn’t a monthly archaeology project

Result: you can run a large, multi-site HVAC operation across the UK & EU with a smaller back office, lower overhead, and higher control, staying efficient without turning into a bureaucracy.

In plain English: bigger operation, fewer people, better output.

Quick recap: the “Power of Three” HVAC growth formula

- Compliance without chaos (evidence by default)

- Cashflow without begging (sign-off to invoice, fast)

- Assets without mystery (better first-time fix, stronger PPM)

Most Frequently Asked HVAC Questions

What is CAFM software for HVAC?

CAFM for HVAC is software that connects jobs, PPM scheduling, engineer mobilisation, asset records, compliance evidence, and invoicing, so service delivery and audit readiness happen in one workflow.

What should HVAC service management software include?

Scheduling, mobile job sheets, asset history, compliance capture (including refrigerant logs where relevant), customer sign-off, invoicing, and reporting that’s usable by directors (margin, efficiency, SLA, backlog).

How do HVAC businesses scale without adding lots of admin staff?

By standardising processes and using one connected platform, so evidence, updates and invoices are created automatically as engineers complete work, letting a lean A-team run more volume without chaos.

See how Arez connects PPM, assets, compliance and invoicing into one operational system.

👉 Request a demo.