Reactive maintenance is a bit like buying the cheapest umbrella from the corner shop: it feels like a bargain until the first gust of wind flips it inside-out. Suddenly you’re wetter, colder, and far worse off than if you’d invested properly in the first place. That’s exactly what happens when you skip Planned Preventive Maintenance (PPM). The short-term “savings” look good on paper, but in reality, they drain margins, wear out assets, and keep your team stuck in crisis mode.

Real-time, preventive control means issues are fixed before they cost you. Every hour protected, every asset assured.

The Cost of Firefighting

You know the drill. A call comes in, something critical has failed, and your team drops everything to fix it. Stress goes up, costs spiral, and margins bleed.

That is reactive maintenance. And too many teams are stuck in it. Reactive feels cheaper in the short term. But the truth is simple: it is the most expensive way to run.

Why Reactivity Costs More

Reactive maintenance carries hidden costs at every turn:

- Unplanned downtime that disrupts operations.

- Emergency repair rates when contractors and parts are rushed in.

- Shortened asset life, driving up capital spend.

- Team burnout occurs when people run from crisis to crisis.

Add it up, and the price of “saving” on scheduled work quickly overtakes the cost of planning.

Reactivity is not saving; it is margin erosion.

Planned Preventive Maintenance: Control Over Chaos

Planned Preventive Maintenance (PPM) flips the script. Instead of waiting for failure, you address issues before they escalate.

Time-based or usage-based triggers keep every asset on track. Think of it as servicing your car — regular checks that keep performance high, extend life, and avoid breakdowns on the motorway.

The result? Predictability, control, and margin protection.

The Benefits You Can Count

A disciplined PPM strategy delivers returns you can measure:

- Fewer emergencies → no more costly 3 a.m. call-outs.

- Predictable budgets → annual spend becomes forecastable, not guesswork.

- Stronger compliance → every inspection logged, audit-ready at a click.

- Longer asset life → delaying replacement costs by years.

- Lower energy use → well-maintained equipment consumes less.

- More trust → your team shifts from firefighting to foresight.

Margins are not won by reacting. They are won by preventing.

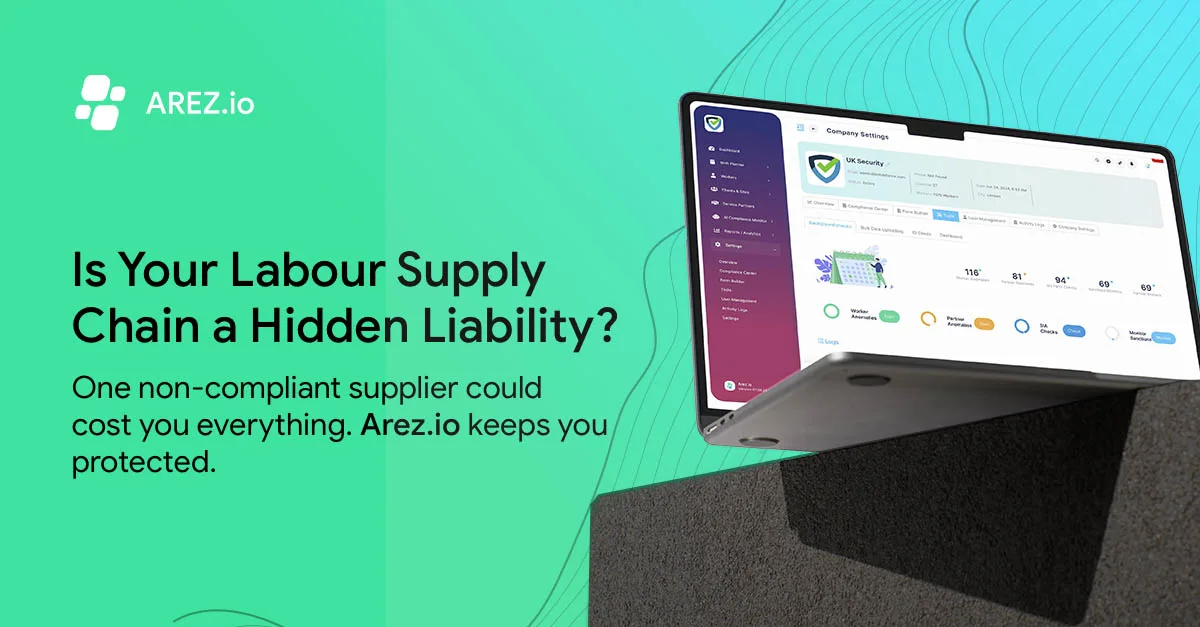

Why a Modern Platform is Essential

Trying to run PPM on spreadsheets is like running Formula 1 on a flip chart. Errors creep in, deadlines get missed, and control slips.

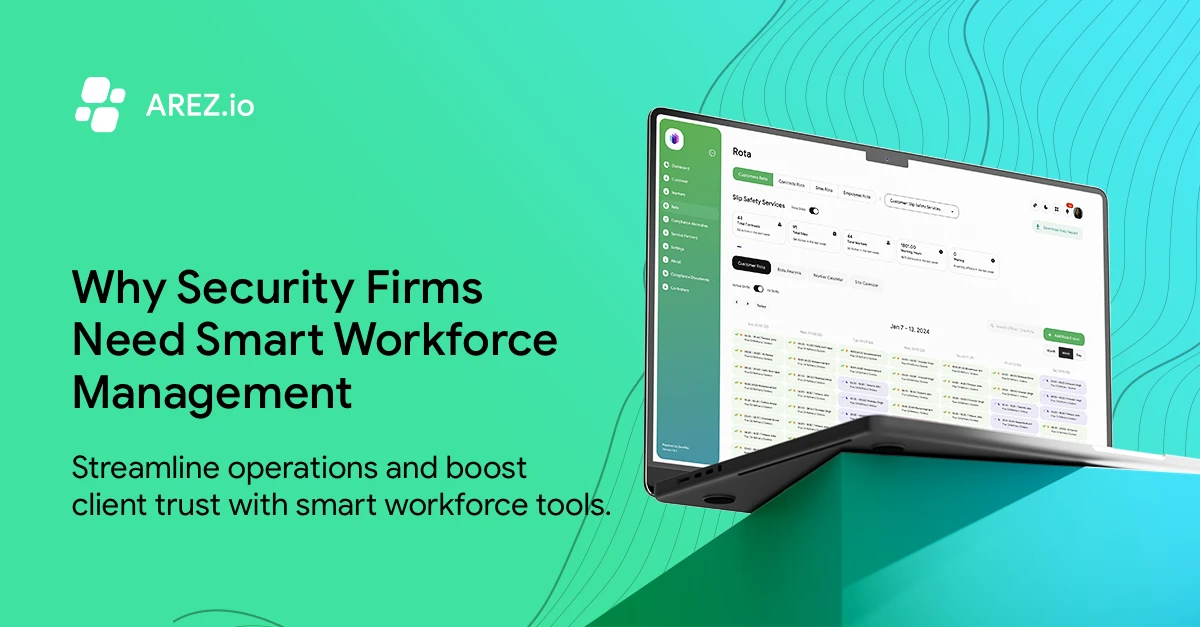

Arez changes the game:

- Central asset register with full service history.

- Automated scheduling so nothing is missed.

- Real-time task management, from assignment to completion.

- Mobile tools engineers update live, on-site.

- Data-rich dashboards tracking cost, compliance, and performance.

With Arez, PPM moves from paperwork to live assurance.

Making the Shift

The transition from reactive to proactive begins with a mindset, followed by the adoption of tools.

- Build a complete inventory of assets.

- Define clear service plans.

- Automate them within Arez.

- Review and refine as the data flows in.

Simple steps. Massive impact.

So, stop battling breakdowns with a soggy umbrella. Call in Arez.io, the god of war for maintenance mayhem. Speak to our team for a quick 20-minute demo, and see how effortless prevention really is. Trust us, you won’t regret it.